Your next-door neighbor just got a rustic red metal roof to complement their modern farmhouse-styled home. And you can’t help but get a little jealous every time you drive by. You begin dreaming about timeless copper roofs and metal mansard roofs, but you don’t know where to begin.

Well, installing metal roofs is a complex process that requires expertise. However, if you want to take on the challenge yourself, we want to help you avoid metal roof installation mistakes.

Before we cover the most common rookie mistakes, let’s talk about the importance of installing your roof correctly.

Why proper installation is key

The treehouse you built in your backyard may be an awesome and solid structure. But, make no mistake– it doesn’t mean you should make metal roof installation your next summer project. Ensuring the proper installation of metal roofing is critical to your entire roof system’s performance.

A new construction metal roof installation must be done correctly to make sure you have a roof that protects you from the elements. So, if you choose to install a metal roof yourself, you must know common metal roof installation mistakes.

Fasten your fasteners!

Fasteners are an important part of every metal roof assembly. They’re any kind of device that’s intended to secure the materials that make up your metal roof. Whether you’re using screws or rivets for metal roofing, you need to make sure they’re put in correctly. This means that they’re not screwed in too tightly or loosely, both of which are popular metal roof installation mistakes.

Because incorrectly installed fasteners can lead to multiple roof leaks, understanding how to dodge these two mistakes is key to keeping the inside of your home dry. So, let’s go over each one.

When they’re too tight

A mistake that most people make when they give a whack at putting up a roof themselves is screwing fasteners too tightly. They think the tighter they can screw in a fastener, the stronger and more secure it’ll be. While this may make logical sense, it’s not always the case and makes for a bad metal roof installation. You shouldn’t feel much resistance when screwing in a fastener. If you do, chances are you’re over-compressing the washer and creating unnecessary stress that can damage or fully break the washer.

You can tell if you’ve over-tightened a screw if the washer is visible and off-centered. If this is the case, it makes your roof a weak candidate for protecting your home.

When they’re too loose

Now, if your fasteners aren’t tight enough, they won’t provide a sufficient seal for the washer. This can result in leaks too, which is why it’s all about finding that sweet spot. In the words of Goldilocks, you want your fasteners to be “just right.” This can be tough to achieve if you’re not a professional. As a result, fasteners that are too loose make the list of common metal roof installation mistakes.

A tip to help you determine if you’ve screwed a fastener too loosely is to check if you can spin the washer. If you can still spin it after you’ve put in the screw, it likely means you haven’t tightened it enough.

Correct fastening is critical

The greatest cause of metal roof leaks is inadequate fastener installation. And, if you live in a northern state that experiences crazy winters, it’s vital that your roof is leak-free. This is why, for example, Minnesota metal roofing is best when done by an expert. Leaks in your roof during the frigid winter months can make your home wet and cold.

Seal your sealant!

Sealant is a material that serves as a barrier against water and airborne particles. It may be used with metal roofing lap joints to create a seam in the roof deck that’s watertight. Most often, the sealant is placed in every area where the roof becomes vulnerable to moisture or debris penetration. Thus, it aids in the prevention of leaks.

A common rookie metal roof installation mistake is to use the wrong sealant. You must use one that’s specifically designed for roofs made of metal. This is because other kinds of sealant or caulking might not effectively stick to your panels. Likewise, sealant for metal construction needs to be flexible so it can expand with the metal.

Don’t forget to reseal

Another popular metal roof installation mistake is thinking the work is done once you finish putting on the initial sealant. The sealant won’t last as long as your metal roof. Meaning, it will need to be resealed at some point. Failing to reseal after your metal or tin roof installation can cause leaks later down the road.

A line of defense for your home

Sealant gives your home an extra line of defense against water, dirt, and other debris intrusions. A buildup of these elements has the potential to compromise the entire roofing system. It can lead to rust, leaks, or serious roof damage. This is why poor sealant application is not a metal roof installation mistake you want to make.

No more oil canning

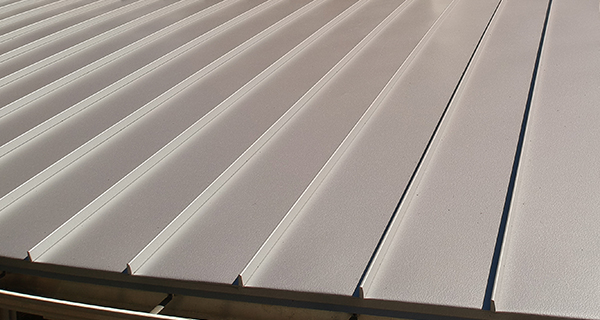

Metal roof installation mistakes must be avoided for proper fit and finish. However, oil canning is something that can– and will– happen on many metal roofs. Oil canning occurs when a roof expands and contracts, causing the metal to look warped or wavy. This effect is impossible to eliminate altogether; but, there are ways to diminish it. For example, you can mitigate the effects of oil canning by using thicker steel or steel with striations rather than smooth panels. You should also avoid fastening the panels too tightly.

We recommend using the thickest steel possible, especially if you want something like a contemporary, sleek ash gray metal roof.

Don’t neglect underlayment

A critical aspect of any roofing system is the underlayment. Underlayment is an important step in metal roof construction, as it gives an added layer of protection. It ensures your roof can protect your home against condensation, which diminishes the chances of damage. Moreover, underlayment included in a metal or steel roof installation aids with insulation. This means that it can keep your home cool and improve its energy efficiency.

Not all roofing panels are equal

Choosing the wrong roofing panels is one of the most common, yet easily avoidable metal roof installation mistakes. There are various types of panels on the market that come in all different shapes and sizes. So, before installing metal roof panels, you have to make sure the panels you choose fit correctly to your roof. The right panel will have the correct slope to match the exact pitch of your roof. Likewise, it’ll have a compatible roofing geometry and engineering design.

Measure everything carefully

It can be easy to get overwhelmed by so many metal roof construction details. That’s why you should have an expert roofer do the work for you. But, if you’re going at it alone, be aware that a timely and costly mistake is measuring your roof incorrectly.

Inaccurate measurements lead to ordering panels that don’t perfectly fit your roof. Thus, it’ll cause a delay and may add extra expenses along your construction process. So, not only should you take measurements before ordering panels, but you should also measure the panels as soon as they arrive.

The easiest way to avoid metal roof installation mistakes

You can avoid a roofing installation mistake the same way you avoid a terrible haircut– don’t do it yourself. If you live in the greater Twin Cities area, hire a professional Minnesota metal roofing contractor to avoid construction mishaps.

To get the best metal roof installation in Minnesota, contact Summit Construction Group today. We’ll ensure the integrity of your roofing system and give you a roof that boosts your curb appeal too.