Whether you are a commercial property owner, a facility manager, a roofing contractor, or an architect looking for low-slope roofing solutions, learning the ins and outs of modified bitumen roofing is to your advantage. This versatile, durable and affordable roofing product can provide the flat or low-slope roofing option that is right for your upcoming project.

Let’s take a look at:

- What modified bitumen roofing systems are

- Benefits of mod bit roofing systems

- Different types of modified bitumen available

- Different installation methods used

- Maintenance and repair considerations

- How to choose the right roofing contractor

Modified Bitumen Roofing: A Primer

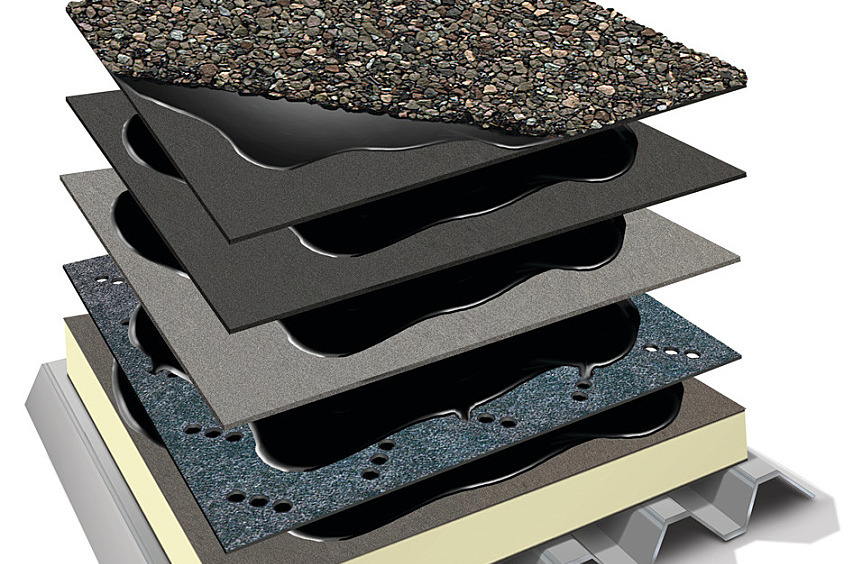

Flat or low-sloped roofs require a different type of roofing system than the overlapping shingle or tile system of higher sloped roofs. Although flat roofs are not completely flat to allow water to drain off, they are designed to hold some standing water for a short period of time. This fact is why they require a different type of roofing system. There are several types of flat roofing systems, including EPDM membrane or single-ply membrane systems, a built-up roofing (BUR) system, or modified bitumen roofing.

Modified bitumen or sometimes referred to as mod bit or MB was first developed in the 1960’s as an alternative to the BUR system that was standard on commercial, low-sloped roofs since the mid-19th century. At first BUR used coal tar and pitch, and later layers of asphalt and roofing felt covered with a layer of gravel. Although heavy, messy, and time-consuming, this flat asphalt roof method was used for the better part of a century before modified bitumen roofing came along. The built-up modified bitumen roof modernized the heavier and messier older built-up system with a lighter, more versatile and cost-effective construction product. It is now one of the most popular flat roofing materials for commercial buildings.

Asphalt has been used in roofing for a long time. It is a petroleum product made from crude oil, crushed stone, gravel, sand, and bitumen, which is a sticky black substance that acts as a binder for aggregate mixtures. Modified bitumen gets its name from this substance.

Modified bitumen is a hybrid roofing construction material that combines asphalt membranes with polymerized rubber or plastic, which are then reinforced with fiberglass. The result is a sturdy yet flexible product that provides excellent waterproof protection and is suited for a variety of applications in commercial, industrial, and residential projects. The modified bitumen roofing system is a durable, multi-layered flat-roof option with weather-resistant properties that perform well in harsher, unpredictable climates too.

Benefits of Modified Bitumen Roofing

High Tensile Strength and Flexibility

Modified bitumen roofing resists tears and punctures due to its high tensile strength, which means it can withstand a high amount of pulling stress without breaking. MB is also highly flexible, which allows it to expand and contract without splitting, cracking, or tearing. These qualities make it a highly durable roofing product, especially in areas that experience extreme temperature shifts, frequent storms or high winds, and heavy rains or snow.

Excellent Waterproofing Protection

One of the issues with low-slope roofs is their limited run off, especially when compared to the natural run-off built into higher pitched roofs. A flat roofing system needs to provide quality waterproofing protection to prevent leaks from penetrating the roof structure and causing property damage. Modified Bitumen has excellent waterproofing ability.

Easy to Install, Repair, and Replace

Modified bitumen is lightweight and relatively easy to install in about one or two days, depending on roof size. It is also fairly easy to repair if it does become damaged and replacing a modified bitumen roof is not difficult or time-consuming either. This makes it an attractive roofing option. It also makes it an affordable roofing solution for most projects.

High Energy Efficiency

Modified bitumen has a high level of UV resistance, which helps improve a building’s energy efficiency, which can significantly reduce energy bills. To further improve energy efficiency, you can also apply a reflective coating to modified bitumen to reduce heat absorption, which can lower cooling costs too.

Some Cons of Modified Bitumen Roofing

Although an attractive flat roofing option, modified bitumen does have its drawbacks. While it is a durable product, the modified bitumen lifespan is between 12-20 years, while a traditional BUR lasts about 20 to 30 years. Other drawbacks of modified bitumen is its high heat absorption, its harmful fumes emitted during installation, and that it is more prone to water puddling compared to other systems. The high heat absorption can be mitigated by applying reflective coating, as explained above. With proper maintenance, modified bitumen can be a great flat roofing option, especially when weighing its drawbacks with its durability, affordability, and easy installation.

Types of Modified Bitumen Membranes

There are variations of the modified bitumen roofing system, which are classified into two main categories: APP and SBS. These categories mean the membrane is basically either made of plastic (APP) or rubber (SBS).

APP Membranes

The first category of modified bitumen membrane is made up of a material called atactic polypropylene or APP. They are composed of asphalt (INSERT) mixed with plasticized polymers. APP membranes maintain their elasticity even in high temperatures and offer a high resistance to UV rays.

SBS Membranes

The other category of modified bitumen membranes is made from a material called styrene-butadiene-styrene or SBS. They are composed of asphalt blended with polymerized rubber. The rubber in SBS membranes give them a natural flexibility. Their elasticity makes them an ideal solution for roofs that are exposed to extreme temperature variations, harsh storms, and high winds.

Installation Methods of Modified Bitumen

A bitumen roofing system usually consists of two or more layers of material and can be installed using a few different methods, including:

- Heat welding or torching

- Hot asphalt mopping

- Cold-process adhesive

- Self-adhering systems

These processes use different types of modified bitumen to adhere the material to the roofing deck. The main types are roll roofing layers or peel-and-stick adhesive.

Heat Welding or Torching

This method of installation uses roll roofing layers of modified bitumen and is installed by a professional roofing contractor that understands how to employ the method properly. In the process the membrane layers are rolled out and heated with a hand-held propane torch, which slightly melts the material so it adheres to the roofing underlay. The seams of the membrane are welded together with the same heating process, creating a consistent seal across the roof’s surface.

Hot Asphalt Mopping

This method is generally used with 3-ply modified bitumen membranes and more closely resembles the process used to construct built-up flat roofs. It involves adhering the modified bitumen membrane to the roof with tar through a hot mopping process and must be done by a professional roofer.

Cold-process Adhesive

This installation method is newer and uses a solvent-based liquid adhesive that does not require heating to adhere the modified bitumen membrane to the roof. The adhesive is made from bitumen, solvent, fibers, fillers and stabilizers and are generally used with SBS membranes. When applied the solvent evaporates and the remaining substances bond the membrane to the roof surface. Cold-adhesives are a newer product with less odor and are considered more environmentally friendly.

Self-adhering Systems

As the name suggests, this installation method uses modified bitumen membranes that are designed with self-adhesive backing. The self-adhesive is protected with a film that is peeled away during installation to adhere the membrane to the roof. These membranes are mostly designed as time saving applications and can also be safer as no open flame is used. However, self-adhesive systems do tend to have shorter lifespans and are often used by facilities managers to save time and money.

Maintenance and Repair Considerations of Modified Bitumen Roofing

As with most things, proper maintenance is often key to longevity. Maintaining a modified bitumen roof goes a long way in extending its lifespan. One of the most important roof maintenance steps, no matter what roofing system or material being used, is to have the roof professionally inspected annually for any damage or defects.

A roofing professional can notice issues that can be easily remedied before they become a problem. Modified bitumen roof inspections should look for signs of membrane degradation, such as grazing, cracks, blistering, slippage, or discoloration. Inspecting seams for failure is also important.

Inspections are also important if damage or leakage is suspected, or the roof has experienced a particularly harsh storm, excessive rain or snow, or extreme weather.

If a roof inspector spots a problem, it is best to repair the damage quickly and to also identify the cause. If the damage is caused by normal wear and tear, a repair can be applied that will help extend the roof’s lifespan. If the damage, however, is due to an installation issue, it may be harder to repair the problem and installing a new roof may be a better option.

Modified Bitumen can be easily repaired with a modified bitumen patch. Repairing SBS or APP membranes often follow similar processes, but will use different adhesive methods. Make sure to follow the manufacturer’s instructions when applying a membrane patch.

The patch is applied by first clearing the area of any dirt or debris. The damaged area of the membrane is then removed and a new membrane patch is cut to fit in its place. The patch is then adhered to the surface and sealed into place.

Choosing the Right Roofing Contractor

If you are a commercial property owner looking to install a new low-slope roof or working with an architect designing low slope roofs, then finding the right roofing contractor for your project becomes a necessity. Not all roofing contractors are well-versed in flat or low-slope roofing construction. It is important to find a contractor that is well-versed in properly installing modified bitumen roofing systems and understands application processes, such as not installing the system in weather below 40 degrees or the parameters involved in different installation methods and materials.

The Last Word on Modified Bitumen Roofing

If you are looking for a versatile, durable, and affordable low-slope roofing solution, modified bitumen roofing can be a great option. It offers strong water proofing qualities and performs well in climates with extreme temperature and harsh weather. If installed properly and well maintained, it can offer long-lasting protection for flat roofs.