PRODUCT TYPES

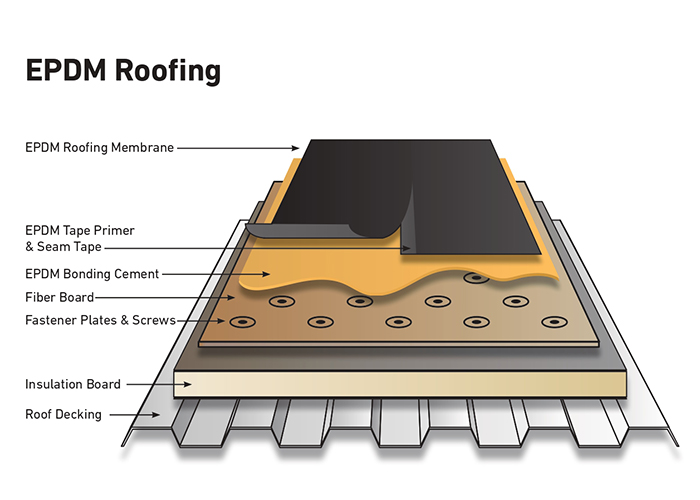

EPDM Is A Tried And True System In The North

EPDM does not expand or contract but it can stretch without cracking when the structure below expands and contracts due to temperature changes. If a full tear out of your existing roof is not in budget, maybe rolling out a new membrane over the old is the way to go.

This can be ordered in large rolls with various widths and lengths. Depending on the size of the area on some residential projects, you can install rolls big enough to prevent any seams or have very few seams. We typically recommend installing fully adhered systems.

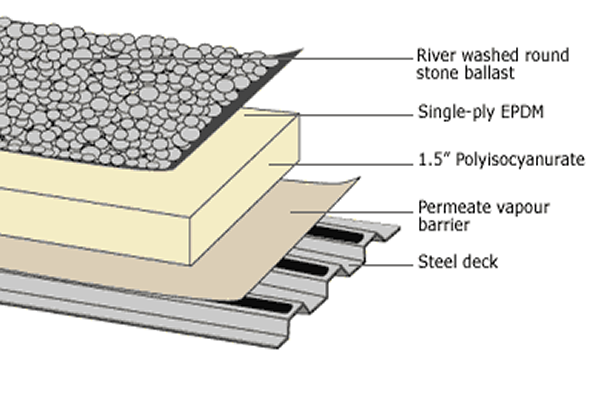

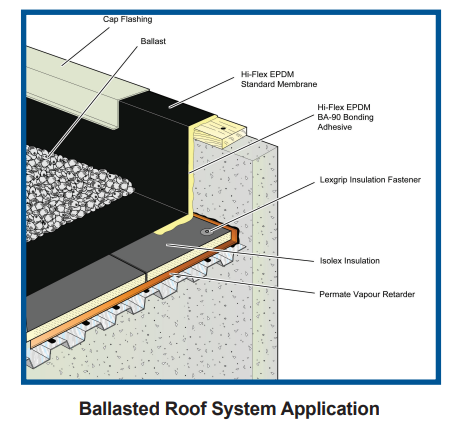

Ballasted EPDM

Ballasted EPDM is more common on flat roofs that have parapet walls and cap flashing around the perimeter. The EPDM is secured to the parapet walls under the cap flashing around the perimeter of the roof and then held in place(ballasted) by rocks that sit on top of the EPDM.

This is a heavier roofing system due to the gravel, but it is a perfect option in situations where adhesion is not possible. An example would be a client wanting to replace a built up roof but avoid the tear out and extra insulation board costs. It might not be possible to adhere to the existing built up roof but the EPDM could be ballasted instead.

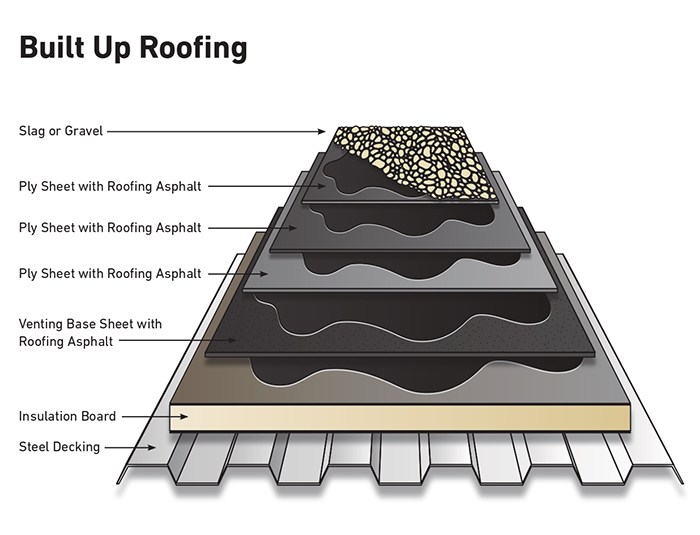

Built-Up Roofing

Built-Up Roofing consists of a base insulation sheet on top of the decking with multiple layers of asphalt, base sheet, ply sheet, and gravel top to create a multiple layer system. If a full tear off and replacement is needed, this system can get more costly. However, this system has some of the best leak resistance, UV protection, and highest thermal rating due to the multiple layers.

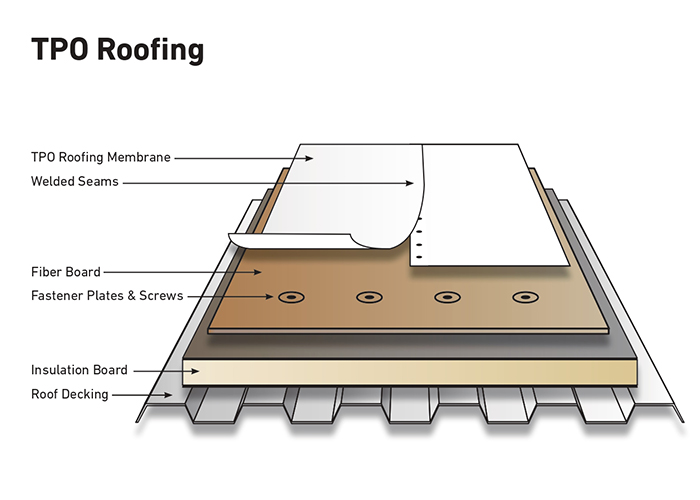

TPO – Thermoplastic Poluolefin

TPO has gained quite a bit of popularity since its introduction 20 years ago and is another versatile option for low slope roofing. It can be glued down, screwed down, or heat welded to the cover plates that are used to hold the polyiso insulation down.

The most talked about benefit of this product is the ability to heat weld each seam, creating a water tight bond between every section of the membrane. Most TPO is white and happens to be extremely UV resistant and more energy efficient on those hot and sunny summer days. This is the most popular material for commercial roofing replacements today.

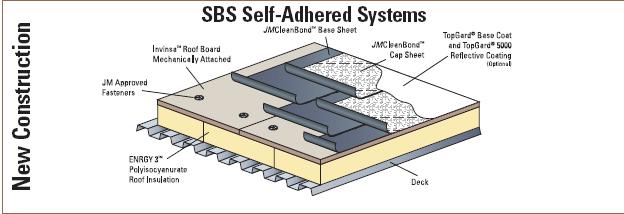

Modified Bitumen – (Rolled Asphalt)

Modified bitumen consists of a base sheet and a top cap sheet. The two pieces create a thick waterproof membrane that is very rugged.

Fully Adhered Modified bitumen works well for smaller areas with a very subtle slope. It comes in rolls that are 3’ wide, therefore it will typically have more seams than EPDM which is why it is suited for areas that are smaller with a tiny bit of slope. It is composed of two parts: The base sheet, which is applied first and adhered to the decking, and then the cap sheet.

Welded (Torch Down) Mod Bit is used in commercial applications and torched down to the base sheet at the seams to provide extra adhesion.

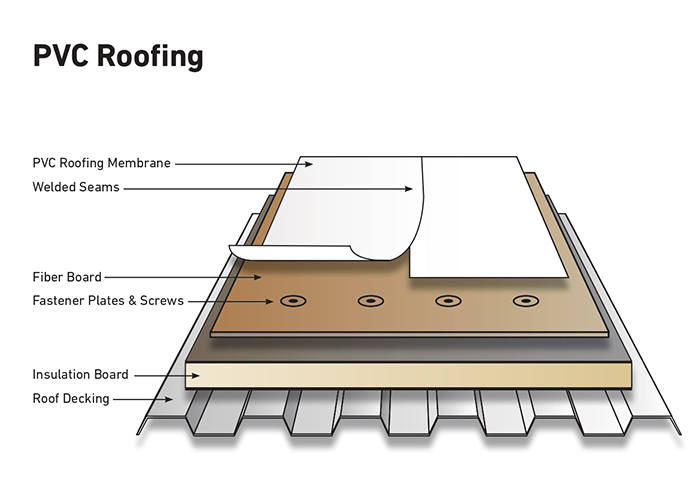

PVC (Polyvinyl Chloride) Roofing

PVC (Polyvinyl Chloride) Roofing is more resistant to chemicals than TPO, a better choice for industrial buildings that could be exposed to harsh chemicals or chemical byproducts.

- Rated for up to 35-year lifespan

- Tear and puncture resistant

- Resistant to grease and most oils, will work well near restaurant ventilators

- Leaks are easy to find and repair compared to roofs with gravel surfaces

- More expensive than TPO

- Resistant to UV Damage

- Fire Resistant

- Cool roof/energy star rated – white membrane reflects heat

- Low maintenance

- 50-80 Mil thickness (60 Mil standard)

- 5-10’ width for most sheets

- Welds at 800 to 1100 degrees

- White, Grey, and Tan colors available

- Smooth or Fleeceback

Connect with Us

Let's Get In Touch

Please contact us for more information about our services or to request a quote.